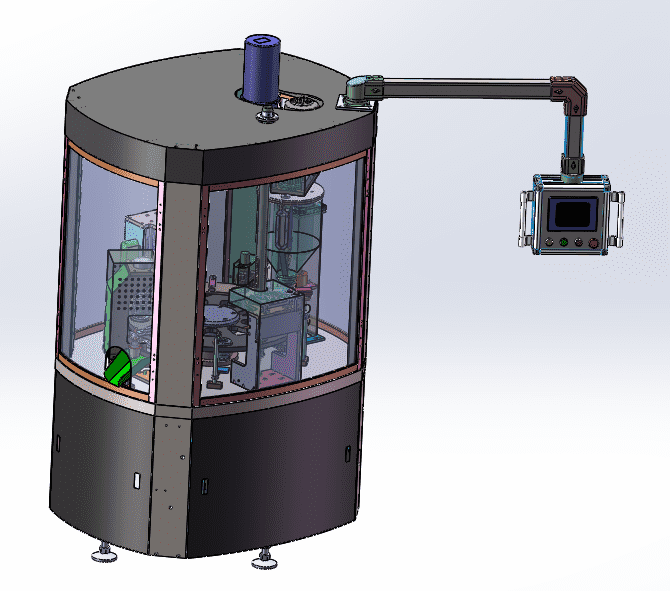

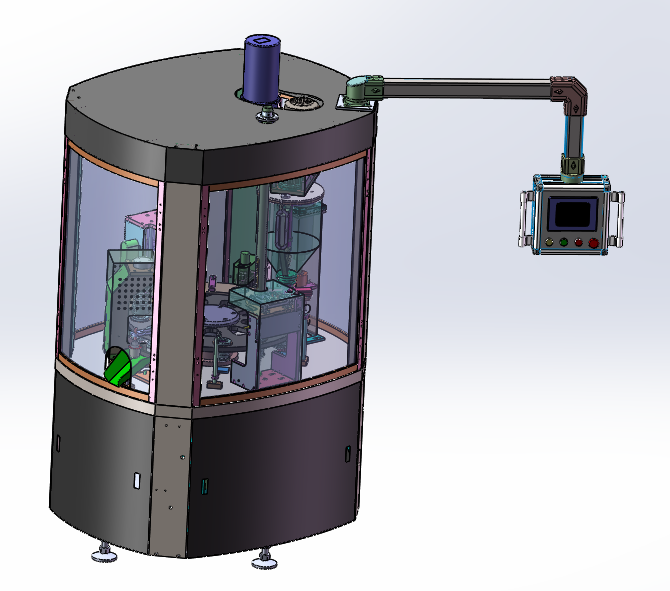

Coffee Capsule Filling Machine

Automatic coffee capsule filling machine

Video reference

Machine Introduction

This coffee capsule filling machine is a new model newly developed by our company. It has a rotating machine, small footprint, fast speed, and stability. It can fill 3000-3600 capsules per hour at the fastest. It can fill a variety of cups, as long as Changing the machine mold can be completed within 30 minutes. Servo control spiral canning, canning accuracy can reach ±0.1g. With the function of diluting, the residual oxygen of the product can reach 5%, which can extend the shelf life of coffee. The whole machine system is mainly based on Schneider, developed by the Internet of Things technology, and can choose a computer/mobile phone to monitor or operate the machine online.

Scope of application

It is suitable for Nespresso, K-cups, dolce Guesto, Lavazza coffee capsule etc.

Main functions

1. The packaging process is completed automatically, the machine occupies a small area and is simple and easy to operate.

2. PLC control system, full-process display and real-time monitoring, and computer/mobile online operation “optional”.

3. Automatically drop the cup.

4. Automatic canning.

5. Automatic cup edge dust removal.

6. Automatically suck and release the film.

7. Nitrogen punching system, nitrogen protection from cup dropping to sealing, the residual oxygen content of the product can reach 5%.

8. Automatic sealing.

9. Automatic cup out.

10. Automatically record the number of packaged products.

11. Failure alarm and shutdown prompt function.

12. The safety is greatly improved.

Machine technical parameters

| Model: | HC-RN1C-60 |

| Food materials: | Ground/coffee, tea, milk powder |

| Maximum speed: | 3600 grains/hour |

| Voltage: | single-phase 220V or can be customized according to customer voltage |

| Power: | 1.5KW |

| Frequency: | 50/60HZ |

| Air pressure supply: | ≥0.6Mpa / 0.1m3 0.8Mpa |

| Machine weight: | 800kg |

| Machine size: | 1300mm×1100mm×2100mm |

Electrical configuration

| PLC system: | Schneider |

| Touch screen: | Fanyi |

| Inverter: | Schneider |

| Servo motor: | Schneider |

| Circuit breaker: | Schneider |

| Button switch: | Schneider |

| Encoder: | Omron |

| Temperature control instrument: | Omron |

| Everbright sensor: | Panasonic |

| Small relay: | Izumi |

| Solenoid valve: | Airtac |

| Vacuum valve: | Airtac |

| Pneumatic components: | Airtac |

Company introduction

Ruian Yidao are one of high end coffee capsule filling machine manufacturer in China.

We have been manufacturing packaging machinery last for 10+ years experience.

We provides all kinds of coffee capsule packaging solutions like Dolce Guesto, Nespresso, K cups, Lavazza etc.

Sincerely welcome customer to contact us for more information.