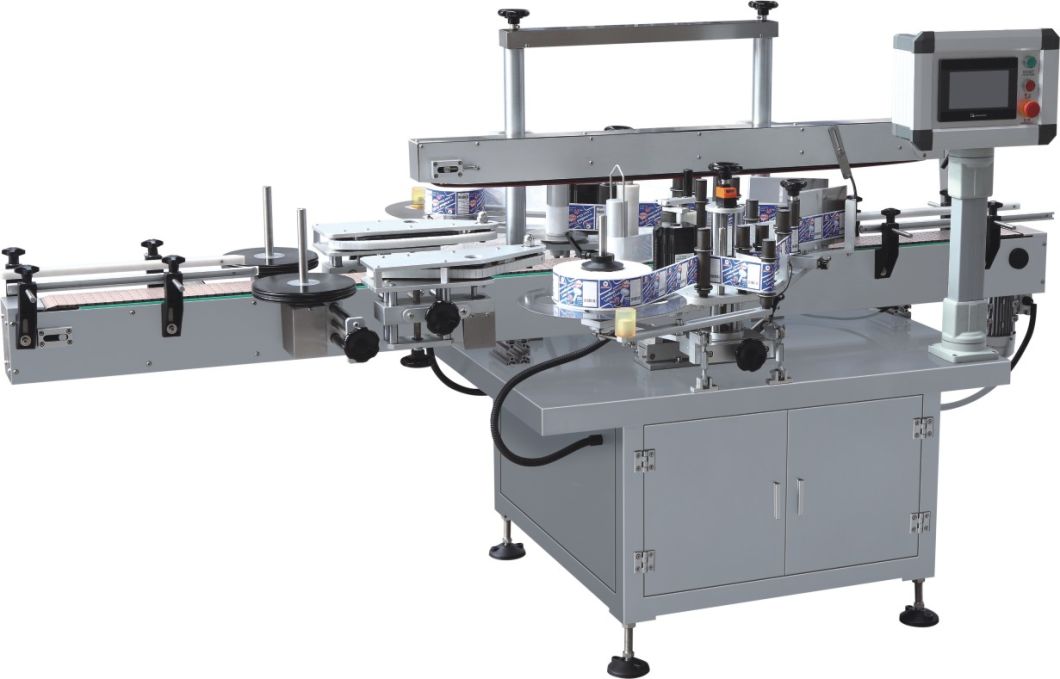

Shl-2510 Automatic Double Sides Labeling Machine

2.Equipment Features

1. This equipment can be affixed to one side or two sides (short labels) of round bottles, one side or two sides of square bottles, one side or two sides of flat bottles (such as shampoo, shower gel, edible oil, lubricant, washing Detergents, eye drops, etc.). It has a wide range of application and strong adaptability.

2. Powered synchronous tension control supply labels, stable and fast supply, ensuring the speed and accuracy of label feeding.

3. The bottle separating mechanism uses a synchronous sponge wheel for stepless speed regulation, and the bottle separating distance can be set arbitrarily.

4. The calibration mechanism uses a synchronous chain to ensure the stability and accuracy of the calibration.

5.The pressing mechanism is adjusted by a screw, with precise movements and a large adjustment range, which can adapt to bottles of various specifications.

6. Synchronous positioning mechanism of the label, the positioning error of the label is plus or minus 0.5mm.

7. Man-machine interface, any abnormal man-machine display and guide troubleshooting, simple operation, anyone can easily operate and quickly use the device.

8. Multi-point emergency stop button, emergency stop button can be installed at the appropriate position on the production line to make the connection operation safe and production smooth.

9. The label peeling distance is automatically calculated by the length and the photoelectricity with the microcomputer. There is no need to adjust the photoelectric position. Any label length can be modified in the man-machine interface, which is convenient to use.

10. The label does not blister due to screw pressing, the servo motor has a screw pressing mechanism on the belt, and the servo motor has a conveyor belt. The speed of the bottle clamping is greater than the labeling speed by about five thousandths of a second. It is the secret that Witt can guarantee that the label will not bubble.

3.Parameter

| Model | SHL-2510 |

| Voltage | AC220v 50/60Hz |

| Power | 1.75KW/h |

| Output (pieces / minute) | 0-180 Pieces / minute (related to product and label size) |

| Operating direction | Left in right out or right in left out (can be connected to the production line) |

| Labeling accuracy | ±0 .1mm |

| Label type | Adhesive |

| Labeling object size | L15-150mm,W10-1020,H40-350mm |

| Label size | L15-150mm,H10-120mm |

| ID of label | 76 mm |

| OD of Label | 360 mm(max) |

| Weight (kg) | 800kg |

| Machine size | 2600(L)820 (W) 1510 (H) mm |

| Remark | Accept non-standard customization |

| Sr. | Product name | Supplier | Model | Qty | Remark |

| 1 | Stepper motor | Huanda | 86BYG250H156 | 2 | |

| 2 | driver | Huanda | 86BYG860 | 2 | |

| 3 | Power supply | Waiwan WM | S-150-24 | 1 | |

| 4 | Touch screen | MCGS | CGMS/7062 | 1 | |

| 5 | PLC | Siemens | SMART/ST30 | 1 | |

| 6 | Frequency converter | Zhejiang Tianzheng | MIN-S-2007 | 1 | |

| 7 | Bottle inspection sensor | South Korea Autonics | BF3RX | 2 | |

| 8 | Check label sensor | South Korea Autonics | BF3RX | 2 | |

| 9 | Alarm sensor | OMRON | E3Z-T61 | 2 | |

| 10 | Conveying motor | WES | NMRV63-10-1.1KW-F1-B14 | 1 | |

| 11 | Bottle splitting motor | Wenzhou dongli | YN90-90W | 2 | |

| 12 | Coding machine | Shanghai | HD-300 | 1 | Option |

| 13 | Stainless steel | SUS304 | |||

| 14 | Aluminum | L2 | |||

| 15 | Relays | CHINT | JQX-13F/24V | 7 |

6. Application

7. RFQ