Automatic Toothbrush Blister Packing Machine

AC-320B High Speed Fully Enclosed Toothbrush Blister Packaging Machine

Scope of application.

This machine is professionally applied to the toothbrush industry, professionally customized for toothbrush packaging. All kinds of toothbrushes, single, double, multiple toothbrush packs can be produced.

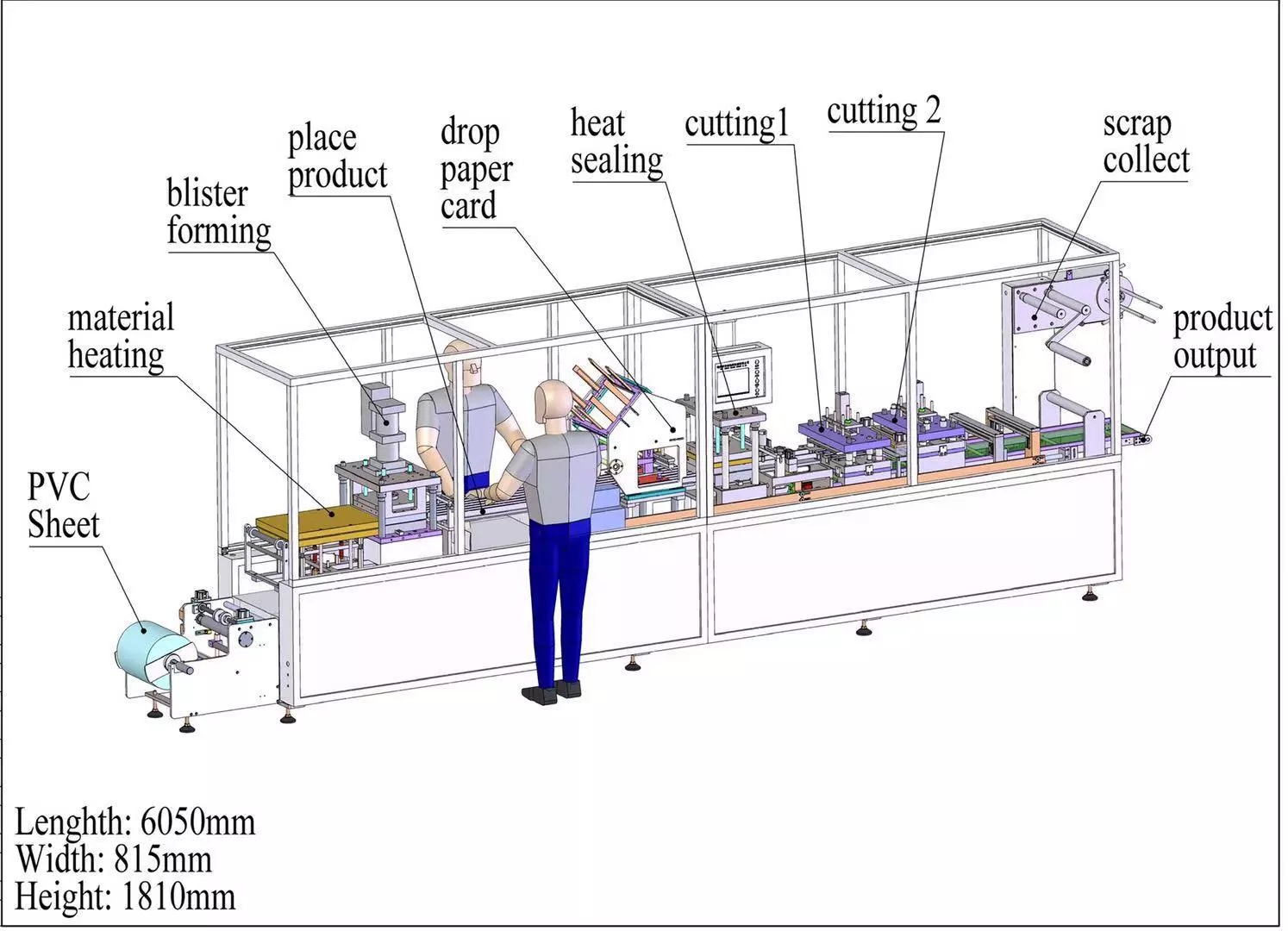

Equipment process flow:

Product Description:

It adopts human-machine interface, PLC intelligent control program, solid-state encoder, support touch screen operation, automatic counting, adjustable stroke speed, accurate and convenient, friction wheel reducer mechanical stepless speed adjustment, stable machine operation, can be applied to different sizes of toothbrush paper-plastic packaging products, convenient operation, durable, clean and hygienic, and equipped with safety emergency stop device can ensure the emergency measures in production, increase the operating safety factor, is currently more convenient intelligent packaging equipment.

1: Mechanical drive, servo motor traction, reasonable structure and simple operation.

2: Stainless steel shell, beautiful appearance, easy to clean, improve the grade of the product.

3: PLC computer control system, frequency control, reduce noise and improve the stability of machine operation.

4: Photoelectric control, automatic detection, improved performance such as operational safety.

5: Integral card feeder to reduce worker labor.

6: Separate design for easy access to the elevator.

7: Design of moulds and automatic feeding methods according to the shape of the package.

Product Specifications

| Packing material: | pvc cardboard (0.15-0.5)×300mm, paperboard 200g-700g, 200×300mm |

| Compressed air | Pressure 0.5-0.8mpa Air consumption ≥0.5/min |

| Power consumption | 380v 50Hz 10kw |

| Mould cooling water | Tap or circulating water energy consumption 50 L/h |

| Dimensions | (L×W×H)5100×1300×1500mm |

| Weight | 2400kg |

| Production capacity | 15-25 strokes/min |

| Stroke range | 50-160mm |

| Maximum board area | 300X200mm |

| Maximum forming area and depth | 400×160×40mm |

Production Workshop Live View

Patent certificate

Patent certificate

CE & ISO9001 certificate:

Packaging

Packaging