Top Quality Tablet Compression Machine - Automatic Multi-Function Rotary Pre-Made Pouch Bag Filling Powder/Food/Package/Packaging Packing Machine – Yidao

Top Quality Tablet Compression Machine - Automatic Multi-Function Rotary Pre-Made Pouch Bag Filling Powder/Food/Package/Packaging Packing Machine – Yidao Detail:

Overview

Bag given packaging machine replaces of manual packing type, which helps large enterprises, small and medium-sized enterprises reach to packaging automation, equipment mechanical grip will automatically take bag, print date, open the bag, to the metering device signal measurement and blanking, sealing, output. Main optional configuration for measuring material filling machine working platform, weight, scale, material hoist, vibrating feeder, finished goods transport hoisting machine, metal detection machine, etc.

It adopts Japan’s latest technology, under the total control system of PLC + POD, adopt mechanical structure, operation gradually replaced the operation of the pneumatic structure, to form a greater demands of the processing technology, easy operation, stable operation, maintenance, easy to clean, beautiful appearance.

Bag given packaging machine replaces of manual packing type, which helps large enterprises, small and medium-sized enterprises reach to packaging automation, equipment mechanical grip will automatically take bag, print date, open the bag, to the metering device signal measurement and blanking, sealing, output. Main optional configuration for measuring material filling machine working platform, weight, scale, material hoist, vibrating feeder, finished goods transport hoisting machine, metal detection machine, etc.

It adopts Japan’s latest technology, under the total control system of PLC + POD, adopt mechanical structure, operation gradually replaced the operation of the pneumatic structure, to form a greater demands of the processing technology, easy operation, stable operation, maintenance, easy to clean, beautiful appearance.

Performance and feature of machine

A. Rapid change of the specifications of the bag, bag width can be automatically adjusted by one button.

B. Single shaft and the CAM design: packing speed faster; more stable operation ; maintenance easier and reduce defective rate.

C. Modular heating, temperature control more accurate, heating fault have alarm prompt.

D. Advanced design idea, reduce the material loss, ensure the stability of equipment operation, extend the operating life of the equipment.

E. Simple and convenient operation, adopts the advanced PLC + POD (touch screen) electric control system and man-machine interface.

F. Machine have wide packaging range , it can packaging : liquid, paste, granule, powder, solid various bagging materials only. According to the different material with different metering device.

G. Machine use preformed bags & packaging design is perfect & good sealing quality to improve the quality and grade of the product.

A. Rapid change of the specifications of the bag, bag width can be automatically adjusted by one button.

B. Single shaft and the CAM design: packing speed faster; more stable operation ; maintenance easier and reduce defective rate.

C. Modular heating, temperature control more accurate, heating fault have alarm prompt.

D. Advanced design idea, reduce the material loss, ensure the stability of equipment operation, extend the operating life of the equipment.

E. Simple and convenient operation, adopts the advanced PLC + POD (touch screen) electric control system and man-machine interface.

F. Machine have wide packaging range , it can packaging : liquid, paste, granule, powder, solid various bagging materials only. According to the different material with different metering device.

G. Machine use preformed bags & packaging design is perfect & good sealing quality to improve the quality and grade of the product.

Parameter of machine

| Model | ZP8-200/ZP8-260/ZP8-320 |

| Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

| size | W:50-200/100-250/180-300 |

| Filling range | 10-1000g/20-2000g/30-2500g |

| Packing speed | 10-60bag/min(speed is determined by the product filling quantity) |

| Average precision | ≤ ±1 |

| Total power | 2.5KW |

| Dimensions | 1900mm X 1570mm X 1700mm/2000mm X 1570mm X 1700mm/2100mm X 1630mm X 1700mm |

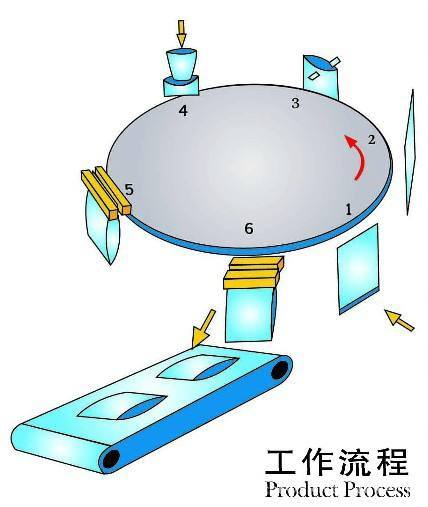

| Work flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

| Applicable scope | 1. Block material: bean curd cake, fish, eggs, candy, red jujube, cereal, chocolate, biscuit, peanut, etc |

| 2.Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer | |

| 3.Powder type: milk powder, glucose, monosodium glutamate, seasoning, washing powder, chemical materials, fine white sugar, pesticide, fertilizer, etc | |

| 4.Liquid/paste type: detergent, rice wine, soy sauce, rice vinegar, fruit juice, beverage, tomato sauce, peanut butter, jam, chili sauce, bean paste | |

| 5.Class of pickles, pickled cabbage, kimchi, pickled cabbage, radish, etc | |

| 6.Other bagging materials | |

| Main standard parts | 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

Machine of models

1,ZP8-200: Apply the bag width :50-200mm

2,ZP8-260:Apply the bag width :100-250mm

3.ZP8-320:Apply the bag width :180-300mm

Working flow

Samples

Factory photos

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Top Quality Tablet Compression Machine - Automatic Multi-Function Rotary Pre-Made Pouch Bag Filling Powder/Food/Package/Packaging Packing Machine – Yidao , The product will supply to all over the world, such as: French, Sydney, Hyderabad, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of good quality, reasonable price, the first-class service. We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

With a positive attitude of regard the market, regard the custom, regard the science, the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Write your message here and send it to us